Industry 4.0 - Smart Workshop Solutions

HopeRun relies on more than 10 years of experience in the automated data analyse field, with a highly competent business design and R&D team. We invented the solution called Industry 4.0 smart workshop. The smart workshop is a set of high intelligent closed-looped manufacturing execution systems that integrates advanced technologies such as accurate indoor positioning, video linkage, audio command, AI recognition, and IoT, which consist of the 4 core capabilities:

Manufacturing transparency: ability to respond quickly to abnormalities in the manufacturing process

Production intelligence: with the help of data analysis, accurate production time, upstream and downstream connection, and precise monitoring of the entire production life cycle can be achieved. This leads to great improvement in production efficiency.

Decision support: detailed decision-making process produces intuitive decision and accurate results.

Predictable quality: Accurate quality trends, produces effective quality control of defects

Problem Solving:

Automation of commands to reduce human intervention

Improve working efficiency in a production line, while providing real-time monitoring and work path traceability

Improve production intelligence, hence reducing unit production costs

Product Features:

Through accurate indoor position, video tracking linkage, voice intelligence, and AI image recognition technology, the manufacturing execution systems are improved.

Open up human-machine information flow, actualize the automation of personnel scheduling, production process, and real-time information communication.

Power Transmission and Transformation - Smart Line Solutions

HopeRun power transmission and transformation – smart line solution applies artificial intelligence to monitor power transmission and transformation equipment. Through the application of intelligent edge devices and AI professional models, the power transmission equipment monitoring system has perceptual intelligence, computational intelligence, and cognitive intelligence, which will improve the efficiency of power transmission as well as its safety, reliability and economy.

Problem Solving:

Low time consumption: For example, video inspection takes several weeks to inspect a transmission line, which does not meet the needs of real-time business development

Alarm lag: It is mainly based on post-event inspection, and cannot achieve pre-warning and real-time alarming.

Features:

End-to-end cloud collaboration: device-side collection, distributed edge computing, display of cloud-based business integration

Edge AI analysis: The edge AI operation analysis with up to 4TB of computing power can analyze multiple video streams in real-time, and improve the efficiency of operation inspection and violation inspection.

Power Transmission and Transformation - Smart Substation Solutions

Smart substation solutions by HopeRun connect substation fixed monitoring cameras and robot monitoring equipment, which formulates perfect identification strategies according to the visual range, location of different cameras, and different AI in edge devices. These are done while computing at the same time that performs different recognition tasks.

The application of system will improve efficiency of substation inspections, reduce the probability of accidents, improve utilization rate of video data and receive pre-warning, real-time warning and post-event tracking of abnormal problems through 2 applications: intelligent identification of hidden defects and intelligent identification of violations.

Core Functions:

Foreign body intrusion detection

Abnormal identification of outdoor equipment

Abnormal identification of indoor equipment

Fire identification

Identification of staff violations

Power Transmission and Transformation - Smart Business Hall Solutions

By accessing the videos in different areas of the business hall, the artificial intelligence algorithm model is used to identify and analyze the public area and work area. It can improve the service image and capability of the business hall, provide data support, and a strategic basis for customers to conduct active diversion. While Internally, it helps to improve the standardization of the business hall, improve security capabilities, and ability to match city-level monitoring.

Core Functions:

Crowd flow statistics

Hall staff etiquette identification

Facial recognition

Informative identification

Alarm center

Alarm linkage

Integrated Energy - E-Commerce Platform Solutions

The e-commerce platform locates ordinary customers, comprehensive energy companies and external service providers, establishes extensive connections between customers and products, needs and services, projects and funds, as well as information and markets. This solution focuses on building sales support capabiilties for applications, equipments, services, etc., horizontally connecting different e-commerce platforms, upstream and downstream service systems, vertically opening up online and offline transactions, and off-net payment systems, creating a new comprehensive energy three-dimensional e-commerve business system, revitalizing the use of ecological resources to promote the collaborations and sharing of resources.

System Features:

Business separation

Build 11 centers + 1 APP application

Proactive defense + risk management + R&D security model to ensure normal operation of the platform

Intelligent Warehousing - Augmented Reality (AR) Operation Assistance System

Based on two application scenarios of warehouse sampling and remote inventory, HopeRun designed and developed an intelligent warehousing-AR operating assistance system. The system includes AR background management application and client application, which can realize seamless connection with Enterprise Resource Planning (ERP) and other systems, and access to the AR intranet.

Users can access the intranet information through warehouse access platform for business data and video interaction. Through AR system, we can effectively manage and control key links such as sample sealing and inventory checking, while reducing management error risks and integrity risks. This will lead to management efficiency and economical benefits.

Main Function:

Warehouse sampling task management

Warehouse remote inventory task management

Real-time task management

AR on-site auxiliary operations

AR cargo inventory

AR audio and video communication

Power Distribution - IoT Smart Stations Solutions

The application of smart station solution relies on the data collection of the lower-level equipment in the low-voltage distribution area. The function of automation studies the power outages, real-time monitoring of energy consumption and load, power quality analysis could help realize lean management of line loss. The equipment ability to perform sensitive and accurate sensing, interconnection, intercommunication between equipments, support rapid development of internet energy, form cross-professional data sharing and shared ecosystem fulfil the need of data distribution network.

System Features:

Minute-level collection of electrical quantities and state quantities through edge proxy devices and intelligent sensing terminals

Real-time connection of marketing and production systems, full awareness of status in the station area

Accurate fault location and proactive repair

Online monitoring and intelligent inspection

Lean management of line loss

Problem Solving:

Improve accurancy and frequency of data collection

Automatic identification of topological relationship of low-voltage station and display in the map

Improve faulty location accuracy and repair efficiency

Stay updated on equipments operating status and better control over equipment in the area

Quality Monitoring and Optimization Solutions

With the development of civilization, the iron and steel industry, chemical industry, subways, and electrified railways are increasing in numbers which requires a high-quality power grid system. This solution detects and manages all aspects of power generation, transmission, distribution, power transmission, and power consumption in the power grid. Thus, an improvement in the ability to solve power quality issues, digitization, network, automation, standardization, and intelligent construction ideas can be achieved.

Energy Information Service

With years of professional experience in power grid automation, HopeRun actively explores the energy field and provides professional solutions for energy management in industrial parks, new energy, power plants, and other business fields by focusing on resource integration to create higher value for customers.

Smart Grid Information Service

Through years of experience in business research and technology, HopeRun is able to assist clients in automated planning and construction with mature, diversified service models and professional customised solutions. This will improve project construction efficiency and success rate. Today, we have served clients from all provinces, mainly electric power enterprises, electric power scientific research institutions and affiliates electric power companies.

Edge AI Analysis Box

| Video Parameters | |

| Computing power | 4T |

| Access resolution | 2K/1080P/720P |

| Video decoding | H.265/H.264 |

| Video output | 1CH HDMI output (3840x2160@30Hz,1920x1080@60Hz,1280x1024@60Hz) |

| Internet function | |

| Network protocol | TCP/IP,UDP,HTTP,DHCP,FTP |

| Interface protocol | RTSP, ONVIF |

| System upgrade | Support remote upgrade |

| Interface | |

| Network interface | RJ4510M/100M/1000M network self-adaptation |

| Alarm input | 4CH |

| Alarm output | 4CH |

| USB interface | 2 x 2.0 USB |

| Reset button | 1 |

| HDMI interface | 1 |

| Indicator light | 4 x status indicator, 1 x power indicator |

| Conventional | |

| Operating temperature | `-30⁰C ~ 70⁰C |

| Working humidity | 0% - 90% |

| Power supply | DC12V/2A |

BUILT-IN SOFTWARE

Embedded Service

Video codec service

Video streaming protocol exchange service

AI model round-robin load service

Log service

CUDA instruction service

Optional Generic AI Model

Person recognition

Face recognition

Expression recognition

Vehicle identification

ID/Driving license recognition

Flame recognition

Temperature identification (requires thermal imaging equipment)

Customisable dedicated AI models

Crane identification

Recognition of hanging foreign objects

Icing identification

Long pole identification

Work helmet identification

Rusting identification

Flammable Gas Leak Detection Solution

Industrial-grade sensors collect data on the types and concentrations of twelve combustible gases such as hydrogen, methane, and ethylene.

Provide LoRa and NB-IOT solutions to upload data to the cloud platform for storage and analysis.

Send alerts and notifications when gas leaks reach set thresholds.

Leak analysis and prediction using historical data from monitoring systems.

Provide leak source location function.

Passed the relevant explosion-proof certification in China.

Provide gas monitoring management platform, gas monitoring mobile terminal APP.

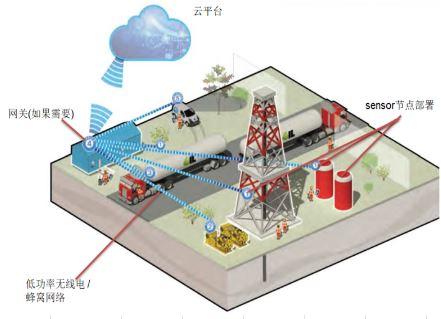

Flammable Gas Leak Detection Solution – Typical Application Scenarios

High-performance sensor deployment

Distributed deployment of high-sensitivity sensors in hazardous areas or key monitoring areas

Low power gateway communication

Selectively deploy gateways according to actual application scenario requirements

Standard data uploads to cloud

Gateway/controller uploads data to the cloud

Intelligent analysis, active alarm

Based on big data and intelligent algorithms in the cloud, it can determine the occurrence of leakage and issue alarms and notifications

SCHEME FUNCTION:

Data collection

Retrieve gas information (type and concentration)

Retrieve environmental information (Atmospheric temperature and pressure)

Data upload

The controller uploads all data to the cloud platform for storage and analysis

Alerts and Notifications

Cloud platform collects data and processes it

The cloud platform provides a place for alarms and notifications send function

Analysis and Forecast

The cloud platform analyzes collected data and makes prediction

Visualize data and graphs

FUNCTIONAL ADVANTAGES:

Advanced Sensor Technology

American NanoTech technology, industry-leading sensor technology

Ability to detect a variety of combustible gasses and mixed gasses

Super anti-virus, long maintenance cycle and long lifespan

Industry-standard, ultra-low power consumption

Adapt to a variety of complex business scenarios

Based on advanced IoT platform technology

Flexible terminal and system deployment options which can be used independently or integrated into tripartite system

Support a variety of wired and wireless protocols, adapt to various mainstream gateways

Standard interface and data layer for easy expansion and integration

Strong technical R&D and support team

It is jointly created by NanoTech, a well-known American sensor company and a listed China’s leading software and overall solution company, HopeRun Software

Leading gas sensor designer and manufacturer

Leading software solutions provider

Years of accumulation of hardware and software, and ability to provide strong technical R&D and product support

Edge IoT Agent Device

Intelligent edge IoT agent management cloud platform is used to manage IoT devices such as edge IoT agents, and implements functions including managing device information, managing applications running on devices, managing data uploaded by devices, and device alarm information.